Custom Harnesses, On-Time, Every Time

RESEARCH AND DEVELOPMENT

Cactus has a R&D team with rich professional knowledge. They have been in the wire harness industry for more than 10 years. From the design of the wire harness, sample verification, and mass production, all follow the entire process. We provide professional solutions to adapt customer needs, such as improving product durability, improving product is easier to install and improving the water resistance of the product. . .

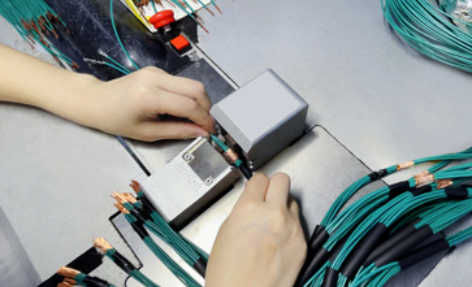

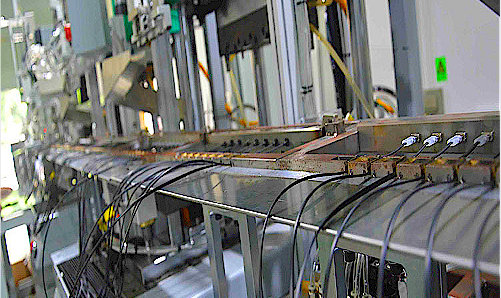

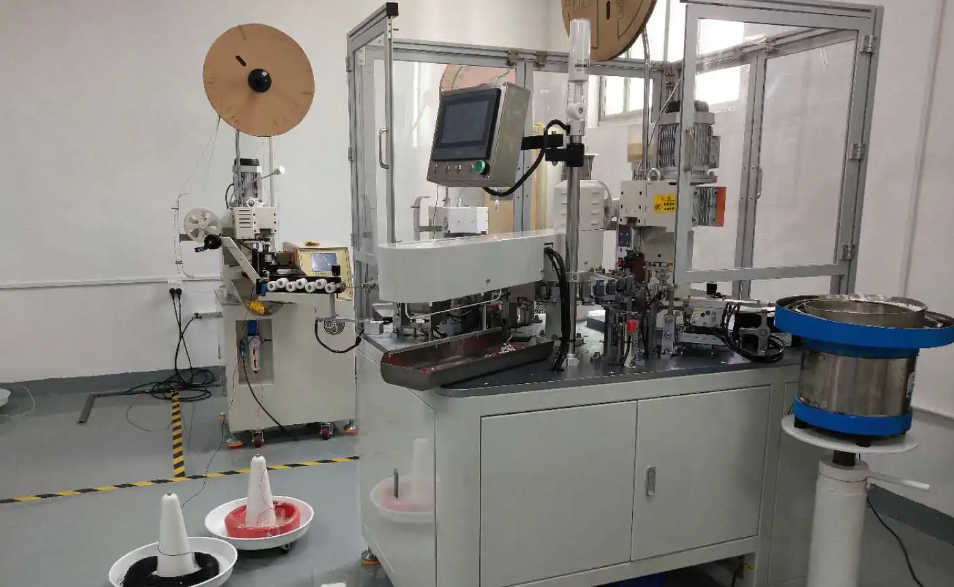

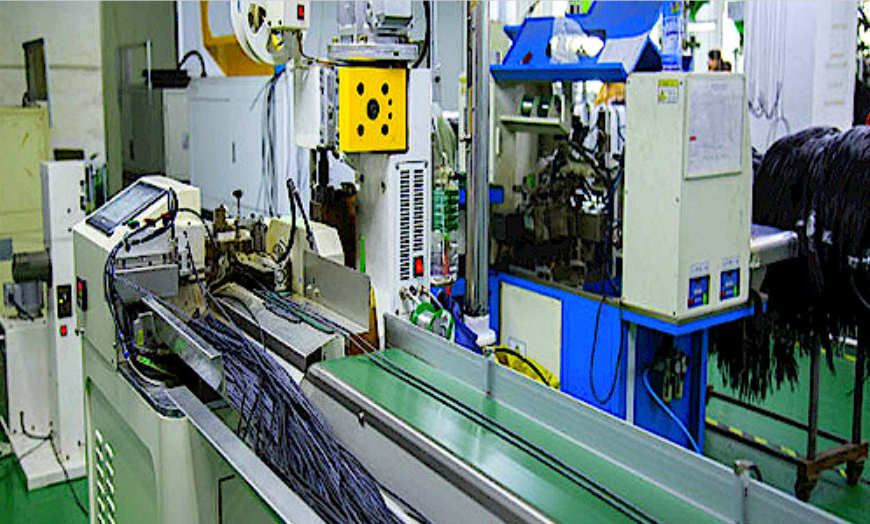

STATE OF THE ART TECHNOLOGY

Cactus keeps up with the technology. Introducing new technologies of high performance and flexibility is our guarantee for the expected quality of our products. Working closely with leading manufacturers of computer-aided and automated machines for the production of complex assemblies, we have achieved superior results that enable combining several types of electrical connections, simultaneous use of a large number of different conduits. In the assembly, final inspection, and testing process, we use our state-of-the-art equipment, which gives us the ability to adapt to new customer requirements.STRONG PRODUCTION CAPACITY

Cactus has two production factories with a total of 6,000 square meters of production workshops and more than 200 skilled workers. With automated machines, 4 million wire harnesses can be produced each year.

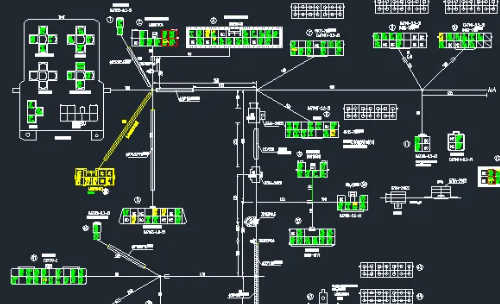

QUALITY CONTROL PROCESS

Cactus was certified by ISO9001, IATF6949, UL. The production of wire harnesses follows the production standard of IPC-WHMA-A-620.The ratio of QC personnel to production personnel is 1:3. We have implemented very strict controls in the entire production process of our products.

The data, pictures and reports obtained in all processes are managed through the ERP system, and all inspection records will be permanently saved.