Custom Cable Assembly Expert

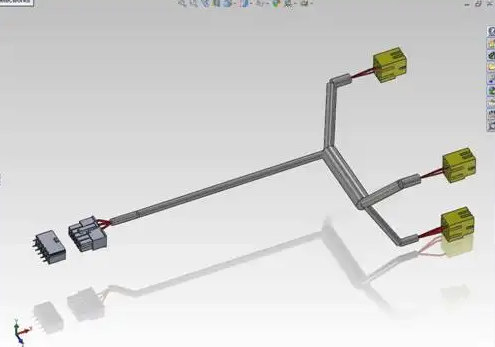

DEVELOPMENT, ENGINEERING AND DESIGN

Cactus provides comprehensive professional assistance in the development, design, manufacture and introduction of standard wire harnesses or complete solutions. Each aspect of the project is overseen by competence centres. With our qualified development team, combining the expertise of mechanical and electronic engineering, we focus on researching and designing the most appropriate cabling solutions for any type of environment. Through state-of-the-art software and our unique vertical integration model, our engineering department is able to be flexible in the selection of products and components and assist in the specification and design of materials.

In Achieving This, We Use Software Supporting:

1. computer-assisted construction with CAD programs;

2. Production Planning with Graphic Support;

3. Construction and process FMEA analysis;

4. Development of control plans for production processes and products;

5. Ability analysis and control of measurement systems and test facilities, including IQC, IPQC, OQC;

6. Document and data management;

7. Statistical control of production processes and key product characteristics (Cp / Cpk);

8. Control and improvement of processes under the PDCA.

Your Competitive Edge With Cactus’ Early Engagement.

Cactus offers vertical collaboration, which reduces R&D costs, production costs, ensures the highest quality and helps put your products on the market as quickly as possible. Together with our customers, we are looking for the most suitable design solutions for plastic and mechanical assemblies, we advise and assist in the choice of materials, which allows rapid installation and ensures compliance with prescribed international standards. We build electrical connections into complete assemblies, thus reducing installation time for our partners.ADVANTAGES OF CONNECTORS

Cactus has three channel sources for connectors:

1. We have established long-term cooperation with many famous manufacturers (such as TE, Amphenol, Molex, Yazaki, samtec, jst, phenix…), and can obtain supply at a relatively favorable price;

2. If you need a more profitable solution, we can also get from our suppliers high quality and compliant alternative products;

3. If you need a customized connector, we can provide a complete set of 3D drawing design solutions, prototype verification, manufacturing mould production, and product certification application (if required).

Our perfect supply chain management and proven R&D and design capabilities ensure we are responsive to customer needs.

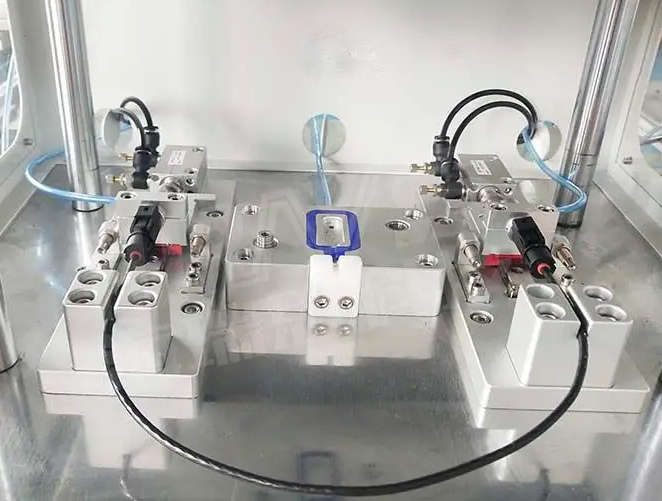

PLASTIC INJECTION MOULDING

Cactus equipment

1. Product injection from 0.6 to 1,500 g;

2. 2K injection moulding technology;

3. A state-of-the-art measuring room with 3D CNC coordinate measuring machines;

4. Own toolshop for maintenance of injection moulding tools;

5. Development of welding technologies and devices for coupling and assembly of plastic semi-products;

6. Machining on CNC turning and milling machines.

Cactus‘ expertise in product development and injection moulding tools, modern equipment and the knowledge and experience of our employees are the guarantee of a first-class product.

Our advanced automated plastic injection molding capabilities provide high production capacity and a high degree of flexibility and quality in finished products. We develop and produce semi-finished and finished products depending on the wishes of the partners.

Development and ability to inject all thermoplastic elastomers into semi-finished and finished technical products with a visible polished or structured surface and with special functional properties on our horizontal and vertical injection machines.